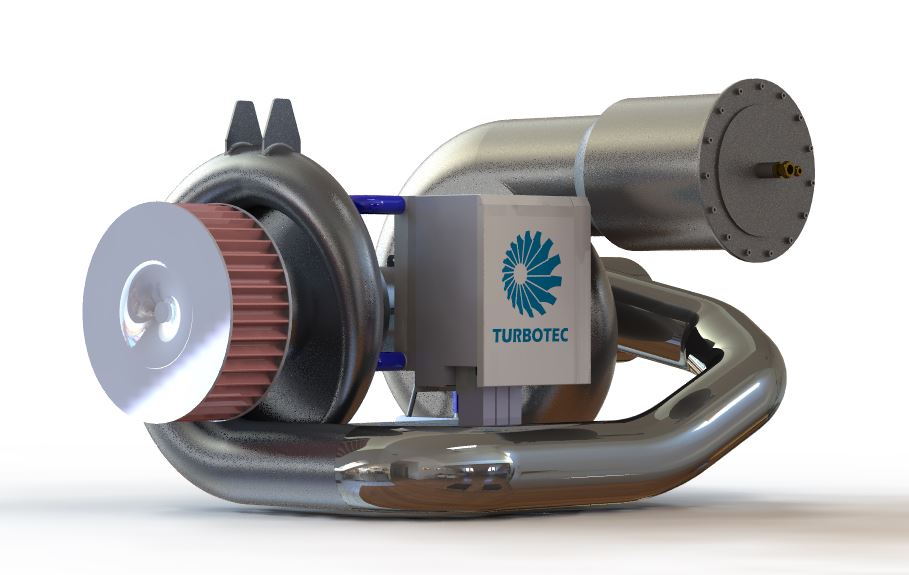

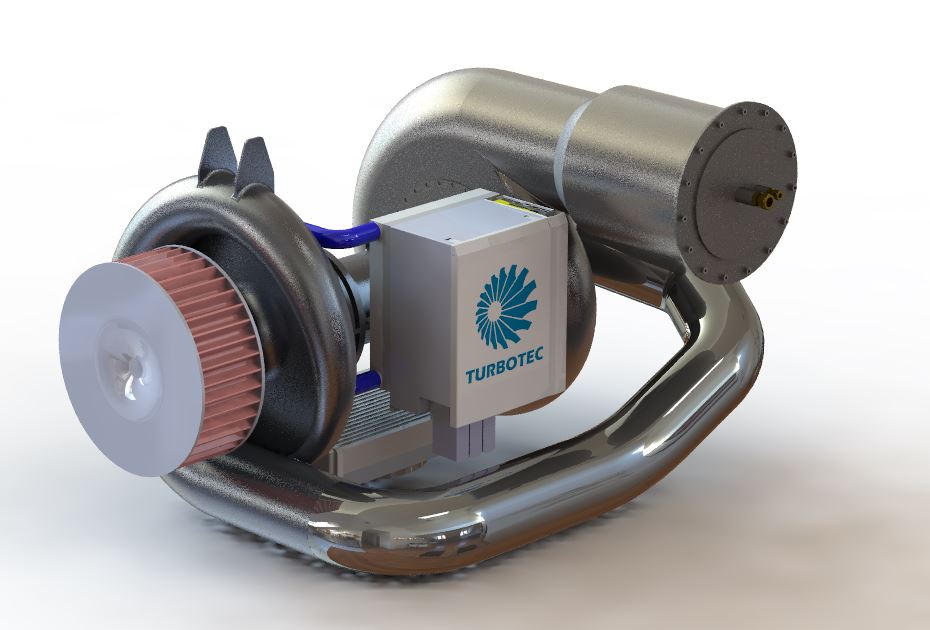

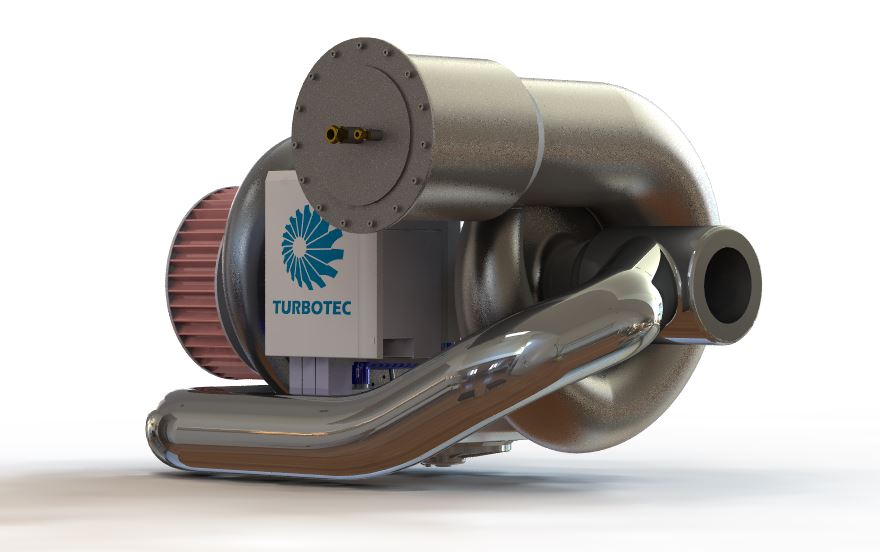

The Black Ghost hydrogen microturbine

TURBOTEC is working together with ThermAero to bring the Black Ghost hydrogen microturbine to market. This micro gas turbine (mGT) has a performance target of up to 12 kW electric output for an installed weight of 14kg. The overall length is less than 600 mm with an envelope diameter 250 mm, with an electric efficiency is above 20% (fuel-to-electric output power).

With its high power-to-weight and power-to-volume ratio the Black Ghost hydrogen mGT is especially suited for aeronautical applications such as hybrid electric propulsion system for drones, UAV’s and small aircraft. The internal recuperating heat exchanger can be sized according to the desired outlet temperature, weight and efficiency, making the Black Ghost also suitable/applicable/useful for a Combined Heat and Power (CHP) setup for stationary applications.

The table below, shows how the performance of the unit changes when the recuperator is sized according to the application:

| Application | Recuperator length & weight | Engine length and dry weight, installed | Electric efficiency (% LHV) |

| Rotary wing UAVs | 200 mm, 4 kg | 500 mm, 11 kg | 15% |

| Fixed wing UAVs, aircraft APUs, hybrid car range extenders, portable generators | 300 mm, 7 kg | 600 mm, 14 kg | 19% |

| Stationary distributed power and CHP systems designed for 24/7 operation | 600 mm, 14 kg | 900 mm, 21 kg | 25% |

With its ceramic recuperator and all-ceramic hot section, the Black Ghost will operate at a high turbine inlet temperature without blade cooling. These innovations will make it the first hydrogen microturbine that can match both, the installed power-to-weight ratio and the fuel efficiency of current internal combustion (IC) spark-ignition piston and Wankel engines, in a single, integrated, affordable package. It will allow microturbines to bring their well-known advantages (5 times longer life and higher reliability, less maintenance, negligible vibration, superior fuel flexibility, and very low pollutant emissions, … ) to markets currently dominated by IC engines.

The Black Ghost is initially designed for 100% hydrogen combustion, but can be adapted to any liquid fuel such as: Jet-A1, diesel, methanol and LNG, or gaseous fuels such as natural gas.

For more information, contact us on info@turbotec.be or via our contact page.

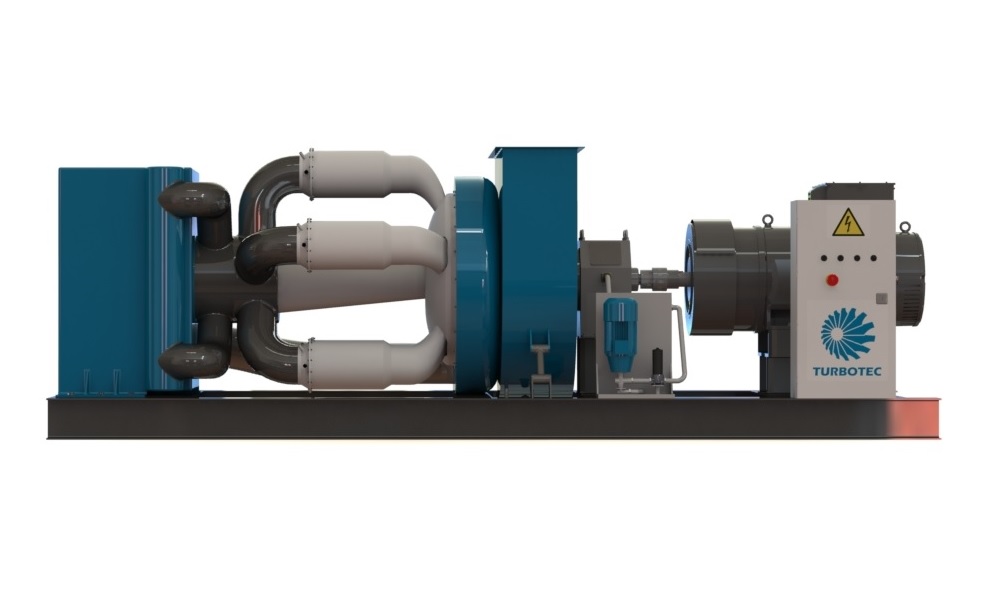

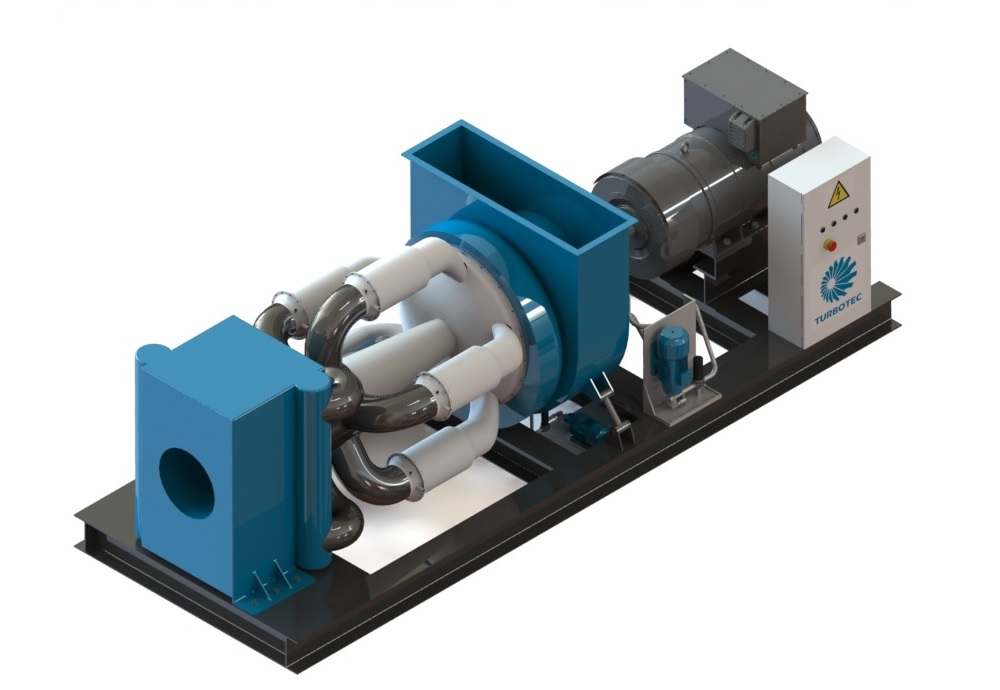

The TURBOTEC HyTG-550

The TURBOTEC HyTG 550 is a hydrogen fuelled gas turbine, designed as a marine propulsion and generator unit. The engine offers 550kW (737hp) of electric power and in a Combined Heat and Power (CHP), it could provide up to 950kW of thermal power. This modular unit can fit in an 20 ft. high cube (9’6”) shipping container. This modular hydrogen gas turbine generator unit can be parallelized to get the desired power output in a larger hybrid-electric system.

- Electrical power 550 kWe

- Electrical efficiency 35%

- Max. fuel consumption 47.2 kg/hr (104 lb/hr)

- Exhaust gas flow 3.1 kg/s (6.8 lb/s)

- Exhaust gas temperature 250 °C (482 °F)

- Required H2 inlet pressure 4.5 bar (65.3 psi)

- Output speed 1500 rpm

- Generator voltage 400/230 V

- Frequency 50 Hz

- Dimensions (WxHxD) 2.35 x 2.69 x 5.89 m (7.71 x 8.83 x 19.3 ft)

- Dry mass (without enclosure) 7000 kg (15500 lb)

- TBO 40000 hrs

The HyTG 100

The TURBOTEC HyTG 100 is a hydrogen fuelled gas turbine generator, suitable for light hybrid-electric helicopters, airplanes and drones. The engine offers 100kW (134hp) of electric power and can also be used as a marine or offshore generator or in a Combined Heat and Power (CHP) unit, where it can generate an extra 170kW of thermal energy.

- Electrical power 100 kWe

- Dry weight 95 kg (210 lbs)

- Dimensions (WxHxD) 1000 x 800 x 1300 mm (39.4 x 31.5 x 51.2 inch)

- Fuel consumption at max. rpm 3.33 g/s of hydrogen at 4.5 bar(a)

- Average fuel consumption 1.96 g/s of hydrogen

Gas turbine: General overview

A gas turbine is a type of internal combustion engine. Air is sucked into the inlet and compressed by the compressor stage. Energy is then added by introducing fuel (in our case: hydrogen) in with the air in a combustion chamber and igniting it so the combustion generates a high temperature flow. This high-temperature high-pressure gas enters a turbine, where it expands, producing a shaft work output in the process.

However, due to the high combustion temperature of hydrogen, the turbine outlet gasses can be used to pre-heat the air entring the combustion chamber by the use of a recuperator. This increases the efficiency of the overall system significantly. Even after the recuperator, the exhaust gasses are still hot enough to be used in a CHP (Combined Heat and Power) system. The hot gasses can be used for any industrial process heating, to produce steam to drive a steam turbine or to heat up water for use in a domestic heating application.

And all this is achieved without any carbon dioxide emissions.

Gas turbine: Compressor stage

The compressor stage in our gas turbine will be a 1-stage centrifugal type that will bring the air up to a pressure of 4.5 bar. The rotor will be milled in Titanium, a strong yet lightweight material. We have already done extensive CFD testing of the entire compressor stage.

Gas turbine: Combustor

Conventional gas turbine combustion chambers cannot burn pure hydrogen; the combustion properties of hydrogen di ffer greatly from conventional fuels such as natural gas or kerosine. Compared to these conventional carbon-based fuels, hydrogen has a much higher adiabatic flame temperature and a higher laminar burning velocity. Because of this, the combustion of pure hydrogen brings with it a higher risk of problems like flame flashback, which can cause catastrophic damage to the fuel nozzles. All of this means that you cannot simply modify an existing conventional burner. A new design, from scratch, has to be made for a gas turbine combustion chamber that burns pure hydrogen.

The preliminary test geometry for the combustor is a partially-premixed single swirl nozzle design. This geometry is used for the CFD simulations, both RANS and LES, to validate the turbulence and combustion models. This test geometry already yields good temperature homogeneity at the outlet, with an average value of 1300°C.

Gas turbine: Turbine stage

The turbine section will be a single stage radial design. To keep the geometry simple, no complicated internal cooling channels will be present in the rotor. However, because of the high inlet temperature (1300°C), a highly heat-resistant yet strong technical ceramic material will be used for the radial turbine rotor.