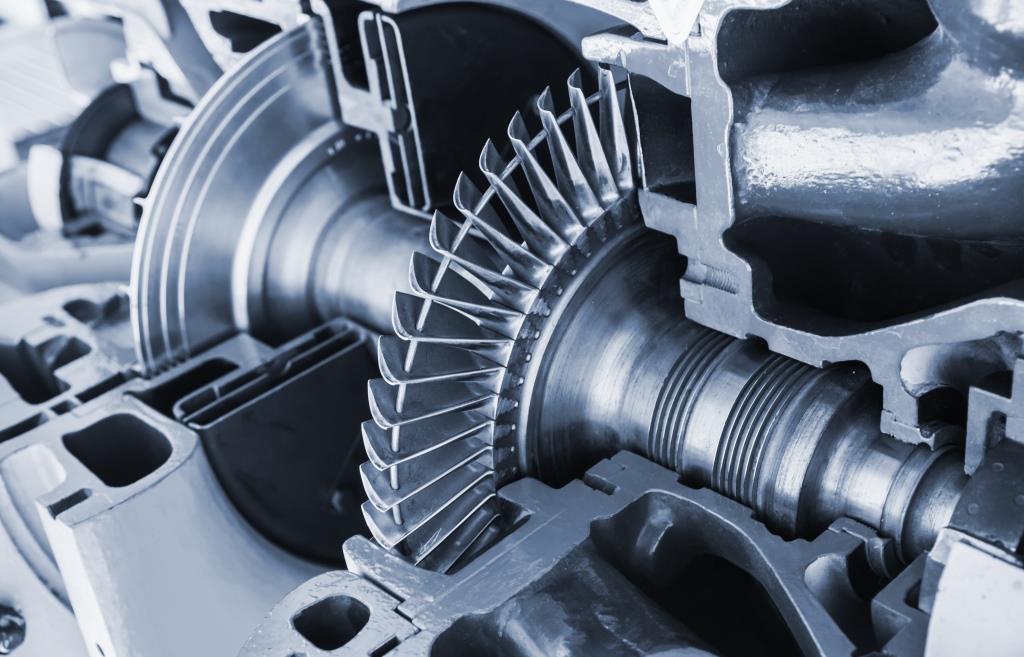

Design of turbomachines

Design of turbomachines is a combination of well established design methods based on theoretical principles of fluid mechanics mixed with a set of experience based coefficients.

Even though several literature sources provide values for those coefficients, they never fail to mention that nothing replaces experience when designing efficient turbomachines.

Although this still holds, CFD assists us in acquiring this experience in building turbomachines virtually and testing them in a way not possible in experiments. It helps us verify our theoretical calculations and allows us to refine the design in an iterative manner.

Prototyping of turbomachines

Theoretical calculations and numerical CFD simulations are only a part of the total design process. To go from preliminairy design, to numerical simulations (CFD and FE) and finally to a functioning prototype ready for testing is a time intensive process that requires a lot of experience in machine design.

Assembly and testing of turbomachines

The CryoFan-20 cryogenic helium blower requires very small clearance gaps in order to attain optimal effciency at 100.000 RPM. Due to the high temperature gradient in the machine from -200°C to +50°C, all parts have to manufactured and assembled to very tight tolerances in a temperature controlled environment. For this purpose, TURBOTEC has access to a temperature controlled measuring chamber with a Mitutoyo 355-9106 Strato-Apex High Accuracy Coordinate Measuring Machine (CMM).